anteryon-customer engagement

from idea to prototype

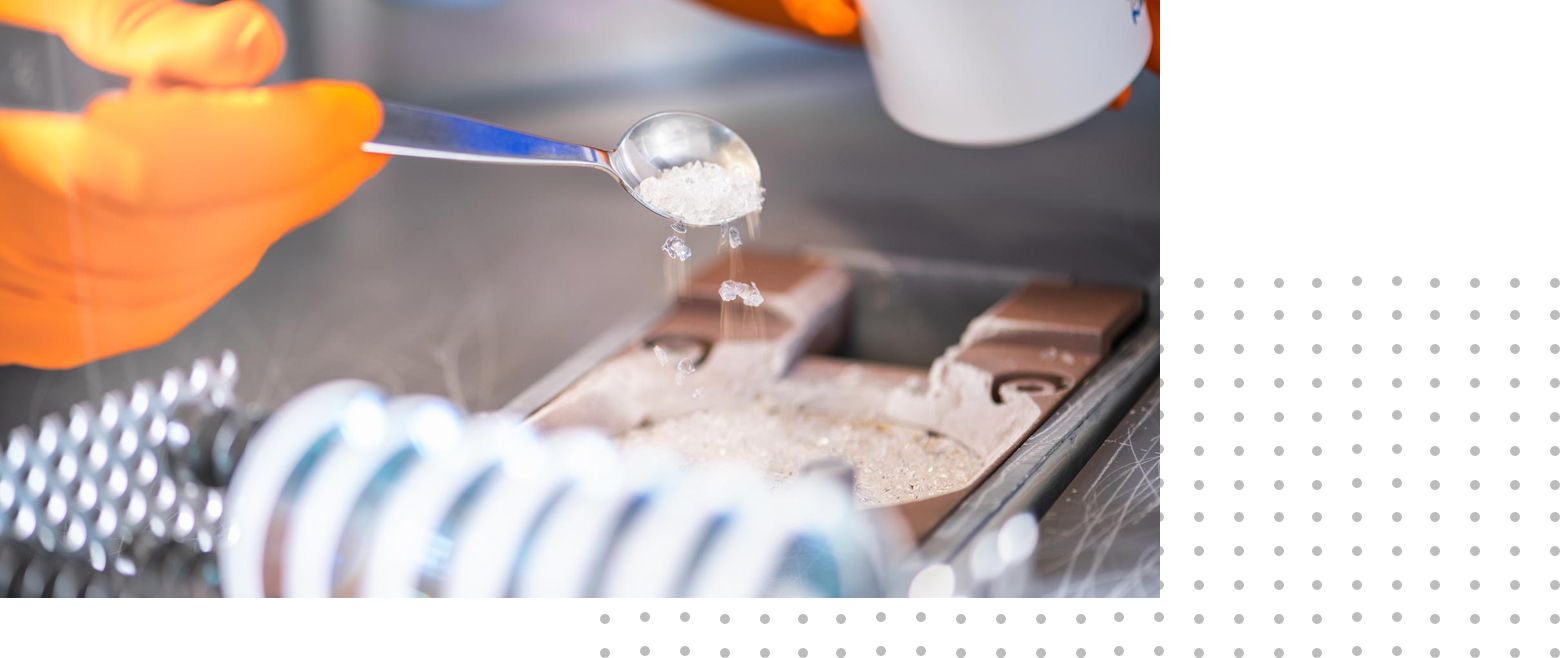

Right from the start, we are eager to brainstorm ideas, do whiteboard engineering with our customers, work out new concepts and explore new design spaces. Our engineers are fully equipped to do detailed optical and mechanical simulations. As a production company, we are able to introduce “design for manufacturing” at the very early phase. In many cases we build your prototype “in-house”, leading to accelerated learning and reduced development cycles.

capabilities:

- Optical and mechanical research and development.

- System engineering and optomechanical tolerance analysis.

- Prototype series manufacturing, using internal and external resources and capabilities.

- Project management and frequent customer communication.

- Functional Testing and Reporting

from prototype to industrial product

We can also take your prototype and turn it into an industrial product. In this case we will review a design thoroughly for efficiencies in volume production. We will discuss possible adjustments with our customer. Together, we will develop the production process, process control, production tooling and equipment and build the production space in our factory. At the same time, we will take steps to identify possible risks and bring down these risks. Critical-to-quality items will be identified and addressed.

capabilities:

- Design for Manufacturing.

- In house production tooling design.

- Reliability Testing / Failure mode effect analysis.

- Technical Product Documentation

- Packaging design (if required).

- Manufacturing Instructions

- Sourcing / Supplier selection for outside parts.

- Project Planning

- Design Release and Industrial Release Sign-off

high volume manufacturing

For over 20 years we have been running high volume manufacturing operations for a wide variety of products. Operators will be trained and certified on specific production tooling. Enterprise resource planning and production planning are integrated in the organization. We have a separate metrology department for incoming and outgoing inspections. And we regularly conduct audits on our selected range of external suppliers.

capabilities:

- Supply Chain Management

- Process Control and Traceability

- Ramp up planning

- Operator Certification

- Metrology department for incoming/outgoing inspections.

- Compliance with international standards

- Quality Management System