We offer various evaporation and sputter coating systems. To realize dense, smooth, and amorphous dielectric, metal and optical coats. And can create fine patterns in these layers with our lithography capabilities.

From high performance coatings on glass and polymer to semiconductor substrates. We offer it all!

Anti-reflection (AR) coatings

Designed to improve the transmission efficiency of the optics, eliminate ghost images and enhance contrast. We can realize a coat dedicated for a single wavelength (‘V coat’) or a broadband coat consisting of multiple layers. Depending on the requirements.

Beam splitter coatings

Designed to split the intensity of incoming light by reflecting a certain percentage and transmitting another. Standards such as 50%R/50%T or 60%R/40%T are available.

Metallic coatings

To realize high reflective mirrors mostly metallic coatings are used. Aluminum coatings offer the highest reflectivity in the visible (VIS) region. Gold or silver perform best in the Infra-Red (IR) range. Depending on the need for high Laser-Induced Damage Threshold (LIDT) Ion Beam Sputtering (IBS) we can provide the highest density coating. Other metals such as Chrome, Titanium, Nickel, and Copper are also available.

Filter coatings

We can also realize coatings with a filter function to transmit only a selected wavelength range. Anteryon makes band-pass filters, dichroic filters, neutral density filters, long-pass filters, and short-pass filters.

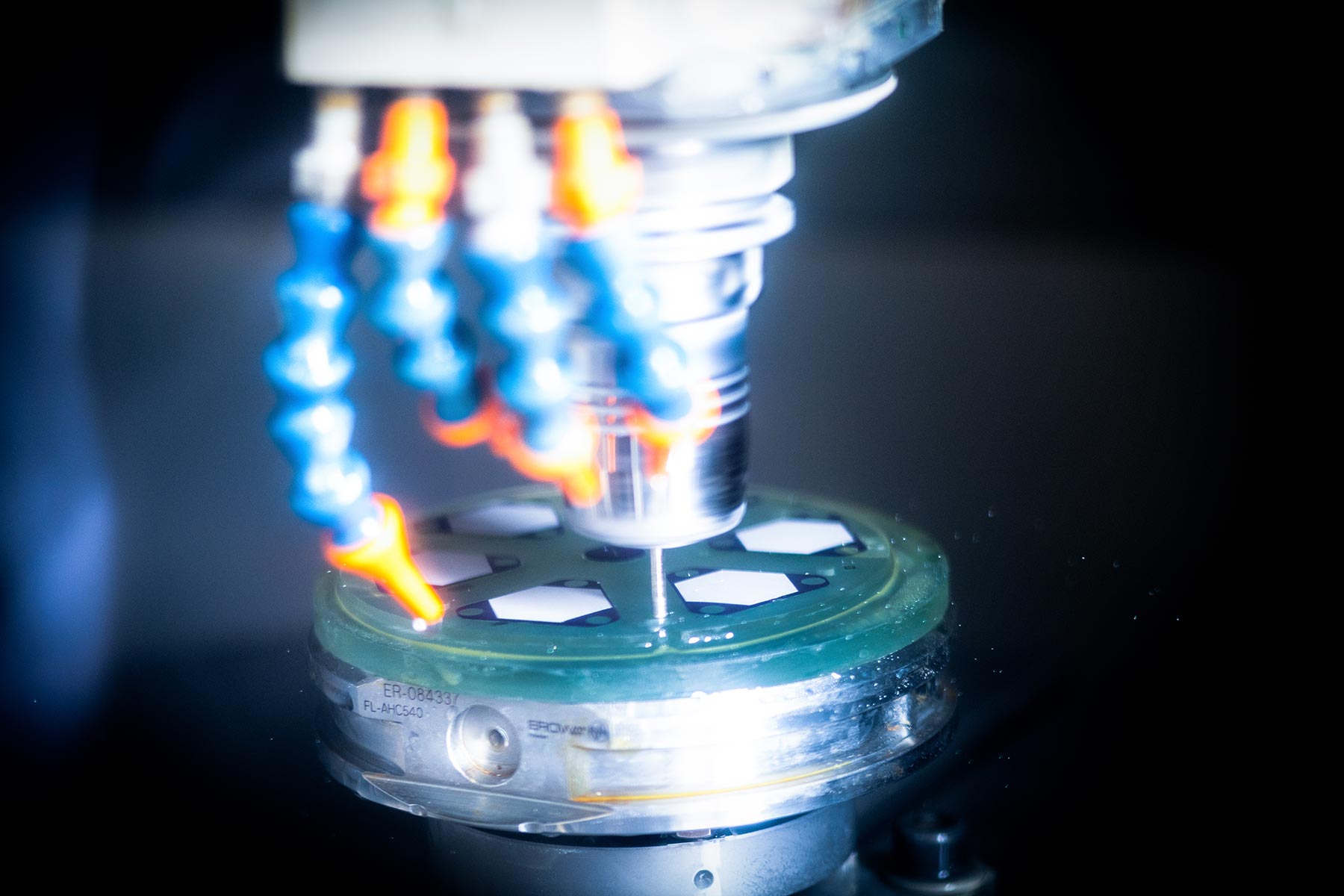

Patterned and stacked coatings

We use lithography to realize fine patterns in coatings and stacks of coatings. Wafers, but also panels (up to 500*500mm) are possible. High-end wet and dry-cleaning equipment, fast and slow baking, profilers and thickness measurement systems, and various wet etching chemistries are available in-house.