-

We achieve highly accurate form and shape tolerances in glass. Via our in-house grinding and polishing capabilities. With laser machining and powder blasting features such as vias, we can realize channels and pillars on wafer and panel scale.

discover more -

We offer various evaporation and sputter coating systems. To realize dense, smooth, and amorphous dielectric, metal and optical coats. And can create fine patterns in these layers with our lithography capabilities.

discover more -

With our own unique low-temperature production process we manufacture high volumes of glass components with nanoscale features. In a surprisingly cost-effective manner. Components like diffraction-limited hybrid lenses and waferoptics® . The possibilities are endless.

discover more -

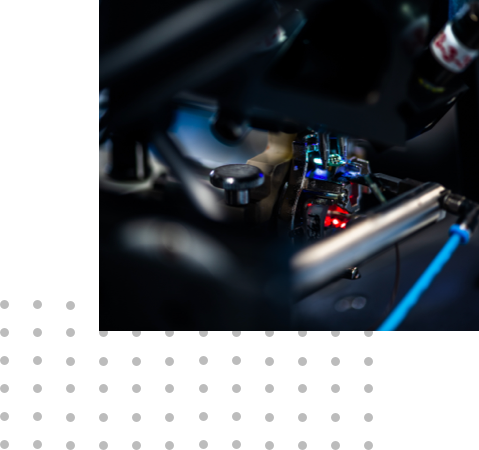

We assemble complex optomechanical modules in our cleanrooms. Combining unique production and highly sophisticated bonding technologies with expert optomechanical design, simulation, and testing skills. All under one roof. To guarantee fast prototyping, short development cycles, and the best system-level solutions.

discover more -

We offer various wafer-scale technologies in-house. From patterning, jetting, and machining to wafer bonding and dicing. All to create packages where active components (VCSEL, LED) can be combined even with integrated apertures and replicated optics.

discover more